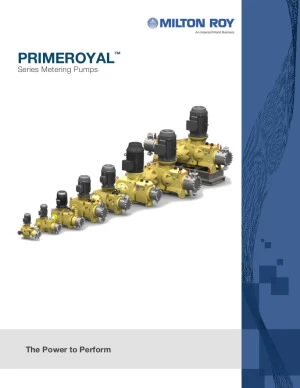

Compliant with API675 standards

- Adaptability and accuracy: capacity adjustable while running or stopped (stroke micrometric adjustment, 10 turns only from 0 to 100%)

- Space constraints: Available in vertical or horizontal motor configurations

- Suitable for the majority of fluids and a large number of industrial processes: several stroke speeds for an accurate dosing

- Modular design to precisely fit your needs: more than five designs of liquid ends, specific check valves, adaptable connection types, control…

- Multiplexing capability: to reduce pulsations, meet a specific flow rate by reducing the number of parts, the power consumption and the footprint or to inject several products

- Long life: ensured by a robust and proven construction, oil bath lubrication to ensure reliability during continuous operation, best materials

- Safety: diaphragm liquid ends guaranteed leak-proof with service life in excess of 20,000 hours

- Operations even in the most extreme conditions: specific configurations to operate in saline/offshore conditions, desert, low temperature environment

- Global design: can comply with the main worldwide certifications and systems: ATEX, NACE, SASO, Customs Union, etc.

- Over-pressure protection: integrated safety valve to protect the pump on diaphragm liquid ends

- Maintenance easy and fast: the patented MARS system (Mechanically Actuated Refill System) avoid the need to delicately adjust the refill valve